突发!杭州一公司车间使用清洁剂不当发生爆炸,企业负责人已被控制

Source: Yongkang Zhongyi Manufacture & Trade Co., Ltd.Publication time:2021-05-17

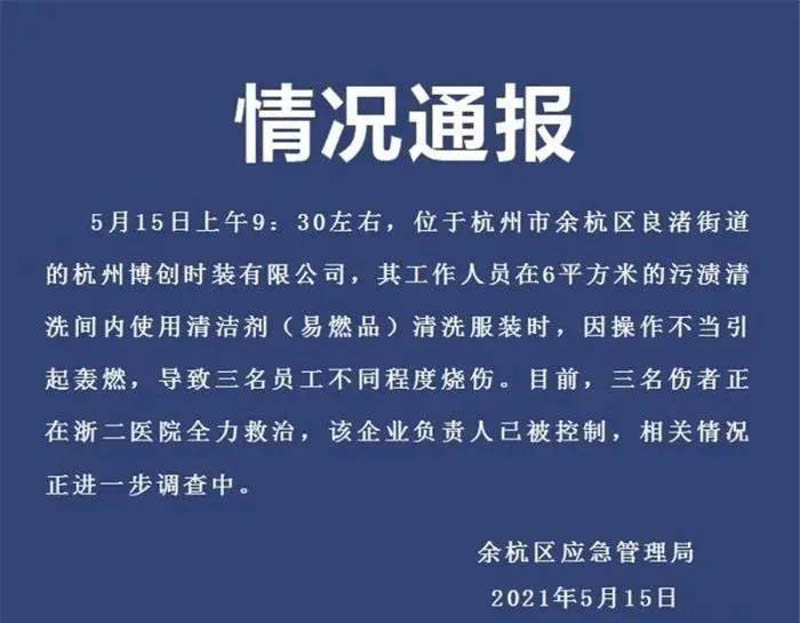

Hangzhou Yuhang District Emergency Management Bureau issued a notice on the 15th. At about 9:30 on the same day, the staff of Hangzhou Bochuang Fashion Co., Ltd., located in Liangzhu street, used detergent (inflammables) to clean clothes in a 6-square-meter stain cleaning room. Improper operation caused flashover, resulting in varying degrees of burns to three employees. At present, the three injured are in the Second Affiliated Hospital of Zhejiang University Medical College (hereinafter referred to as the Second Affiliated Hospital of Zhejiang University), and the person in charge of the enterprise has been controlled.

The reporter learned from the second hospital of Zhejiang University that the hospital has treated 3 patients with extremely severe burns, of which 2 patients with burn area greater than 90% and 1 patient with burn area 70-79%. Emergency measures such as tracheotomy, deep vein puncture and fluid treatment in shock stage have been taken. There is already one in operation.

Video surveillance shooting of deflagration scene

Yes, you're right

This is the scene of the crash caused by the detergent

How did the accident happen???

At the experimental site, firemen opened a bucket of brand-new spray gun water cleaner and poured 2 liters of cleaner into the container. Then, firemen in fire protective clothing went to the No. 1 laboratory and sprinkled 2 liters of cleaner on the ground to restore the scene where factory employees cleaned the oil on the ground with cleaner. After the firefighters sprayed the detergent, they left the room and closed the door. At the same time, the staff began to count the time.

One minute later, the ignition order was issued, and the staff turned on the preset remote control device of electric spark in the room. Only 2 minutes and 11 seconds later, they heard a "bang". The fire of No. 1 Laboratory splashed and rushed out, and most of the roof of the room was lifted. Through the monitoring, it can be seen that the clothes on the three dummies in the No. 1 laboratory have been burned.

On one side, fully armed and well prepared firefighters immediately put out the fire with fire extinguishers and water guns to avoid the spread of the disaster. According to the monitoring instrument, the concentration of isohexane in room 1 reached 15.1% in 2 minutes and 11 seconds.

When the electric spark meets the spray gun water

After that, in lab. 2, the fire officers and soldiers tested what would happen in the process of using detergent to clean up the oil in the same room and gradually heating the heating wire. This is mainly to reduce the machine or other items to a certain degree of heat, filled with detergent room what will happen.

When firefighters also sprinkled a brand of detergent in the experimental room, the electric heating wire with power on for only 9.7 seconds ignited the detergent with a concentration of 1.2%, and caused a large area of fire in the room.

I don't know. I'm scared

After using spray gun water cleaner

A little spark can make a room explode instantly

Interpretation of fire experts

"There are many kinds of cleaners, such as white oil, Tianna water, spray gun water, etc. because of its high fat solubility, high volatility and strong decontamination ability, it is often used as a cleaning agent in industry. However, such cleaners are also particularly flammable. When the volatility reaches a certain concentration, flashover and explosion may occur in the presence of electric sparks or hot objects." He is a doctor of State Key Laboratory of fire science and a senior engineer of Ningbo fire brigade.

actually

White oil, Tianna water, spray gun water and other cleaning agents

They are all organic solvents

The common organic solvents in production enterprises are

Coating, glue, solvent, paint, ink, etc

So, what are the common hidden problems of organic solvents

Take notes now

Common hidden trouble in using organic solvent

Organic solvents are volatile. When cleaning machine and equipment with organic solvents, electrostatic and spark are easy to cause accidents. In mechanical repair, organic solvent can quickly remove rosin, welding trace, dust, oil, salt, metal powder and other substances on the surface of the equipment, without any residue, and the cleaning effect is good, which is a special cleaning agent. However, because of the strong volatility of organic solvents, the vaporized combustible gas is volatile to the air during cleaning, and it is easy to cause fire or even explosion in the event of static electricity, sparks or high temperature.

Excessive storage or improper storage of organic solvents. The production and storage sites cannot store organic solvents in excess. According to the regulations, the storage of production sites shall not exceed the use amount of one day and night. Improper storage can easily lead to accidents and environmental pollution.

Ventilation and exhaust system does not meet the requirements. Organic solvents are used in closed or semi closed spaces, and no ventilation and exhaust equipment meeting the requirements of the specification is set, which leads to the accumulation of combustible gases and accidents.

Use non explosion-proof electrical equipment. Non explosion proof electrical switch is easy to generate electric spark when it is opened or closed. If non explosion-proof electrical equipment is used in the place where organic solvent is used, it will provide fire source for explosion of volatile gas of cleaner, and bury hidden danger for fire and explosion accidents.

Poisoning of people caused by the use of organic solvents. Organic solvents have irritating effect on skin and mucosa, and have anesthetic effect on central nervous system. If the contact personnel do not take effective protective measures, do not wear anti-toxic masks, glasses, gloves, etc., it is easy to cause acute or chronic poisoning.

Safety measures for using organic solvents

The storage container of organic solvent shall be sealed as much as possible, and the open operation shall be avoided as far as possible, and the leakage shall be avoided and the emission of volatile gas of organic solvent shall be reduced. Meanwhile, it is necessary to prevent the external air from entering the equipment container to form explosive gas mixture.

When producing or using organic solvents, the workshop and warehouse shall be equipped with electrostatic elimination facilities, explosion-proof lamps and electrical switches. The warehouse may adopt the method of not setting electrical equipment.

Strengthen the ventilation and ventilation of the environment, carry out comprehensive ventilation for the workshop, reasonably set up the exhaust equipment, and effectively reduce the concentration of dilution solvent in the environment.

Organic solvents must be stored in special warehouses to avoid direct sunlight and high temperature environment, and away from fire sources and oxidants.

Try to use low toxic (non-toxic) solvent instead of high toxic (low toxic) solvent, and set up emergency alarm device and emergency rescue facilities for posts using inflammable and explosive substances.

Just to clean up the oil

But at great risk

Do you want to use those flammable and explosive cleaners and how to use them

Enterprise managers should think twice before they act

Safe production,

The alarm rings!

Please let more people learn!